Convincing case for cloths

And why one type is the all-around winner!

Drying off excess moisture from production surfaces is normally achieved by using materials at opposite ends of the scale in the hygiene vs. cost equation.

To the far left of the scale, where hygiene is deemed more important than cost, the common blue paper towel is widely used. It is very disposable, so definitely only a “one use” product, but because it is comparably so thin it has only limited absorbency before it starts to break up, so consequently a lot of it is used to get the job done.

To the far right of the scale, where cost is the deciding factor, there is a range of reusable wiping materials, mostly cotton based that are used, collected, laundered and dried then reused again. These are normally used over and over until they will no longer stand up to the laundry cycle, at which point they are discarded.

The most common style of this type of wiper is the ubiquitous tea-towel, but flannel style face cloths and even the old style cloth nappies have been used (imagine explaining that one to your overseas customers!)

These cotton cloth style products are all woven, so have the disadvantage that fibres can unravel and be frayed and left behind on the surface they are drying. Using this style of product has always been thought to be more cost-effective than disposables, but this is questionable if you really dig into what it costs to collect, launder and re-distribute them every day.

Well, the Good News is……….as proven in a trial conducted recently at an export lamb plant, the best option from both a hygiene and cost perspective is neither of these traditional materials.

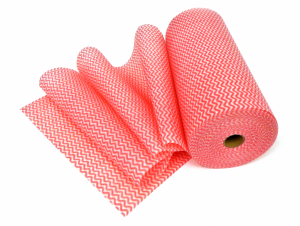

What came out on tops, was the Fibreclean Heavy Duty Wiper Cloth, which is a non-woven 92gsm semi-disposable wipe on a roll, available in four different colours.

In the two week trial, cleaning staff were issued with only these cloths for drying down surfaces after final rinsing, and were not given access to the traditional blue paper towel rolls.

After two weeks, the consensus was that the cloths outperformed the paper towels in all aspects, as reported here:

- Far more absorbent per “piece” than paper and could be used and re-used many times before disposing of.

- Because they hold together so much better than paper, were far less likely to leave pieces behind.

- Micro results over the two week trial improved compared to when using paper.

- Less waste to dispose of.

- Available in four colours, so different rooms could use different colours.

- An estimated saving of six thousand dollars per year on their paper towel costs.

In another situation, a very large commercial bakery was laundering hundreds of cotton face-cloths and re-using after their big weekly clean up. The problem with these cotton cloths were three-fold.

Firstly, being a woven product made of white cotton, they had to be bleached each laundry cycle to keep them looking white, and this eventually breaks down the cotton, and leads to threads being left behind on production surfaces as the cloth slowly degrades.

Secondly, customers were requiring proof that the laundering cycle was actually achieving proper sanitation standards every time they were laundered, and this was difficult to provide, seeing the laundering was outsourced.

Thirdly, the logistics involved in collecting all the face-cloths after use, accounting for any missing, and re-distributing them to each department was a cost that hadn’t been reckoned on initially. Four years ago, this bakery got rid of the face-cloths and swapped out to using the Fibreclean Heavy Duty Wiper Cloths instead, and have never looked back!

One aspect they particularly like is the fact that the rolls of wipes can be quickly placed into the stainless steel holders mounted in any convenient spot, which keeps them off floors and benches and stops them from going missing just when you need them.