Hello Guest,

Food allergies are regularly in the headlines and for good reason. With food allergies affecting up to 10% of babies, 6% of children and 2% of adults, it’s more important than ever to keep track and declare any allergen if you’re a food manufacturer; if one slips through the net, it could put your customers in danger and with it the future of your business. Most are pretty good at listing the common food allergies on their packaging, it’s cross allergen contamination that poses the biggest risk.

What is allergen cross contamination?

What is allergen cross contamination?

Cross contamination is when an allergenic ingredient, not included in the food product recipe, enters the manufacturing process. Undeclared allergens within the product pose potential health risks. Hospital admissions for severe allergic reactions (anaphylaxis) have doubled over the last decade in Australia, USA and UK. In Australia, admissions for anaphylaxis due to food allergy in children aged 0 to 4 years are even higher, having increased five-fold over the same period.

What makes effective allergen cross contamination?

Processes that were seen as suitable five years ago no longer cut the mustard. Procedures now need to be more robust and future-ready. There’s a system known as Horizon Scanning which is employed by a number of the largest corporations in the world. They describe this process as ‘not about making predictions, but systematically investigating evidence about future trends.’

Trying to anticipate potential upcoming risks is the easiest and most cost-effective way to proactively improve your allergen segregation policy. Keeping an eye on alerts from the Food Standards Agency can help keep you ahead of the game and any new legislation. It’s also worth remembering that while there are only 10 allergens that have to be declared, almost any food can cause an allergic reaction; something isn’t risk free just because it isn’t in the legislation.

Ten ways to improve your allergen segregation

Horizon Scanning is great and should definitely be part of your plan going forward, but what should you be doing now? We have ten simple ways to help to reduce your risk of cross contamination.

1. Check your suppliers’ processes

If you’re using an external supplier, you need to know what is happening at their site. Ask them about the allergenic content, what ingredients are affected, and the proportion of the raw material the allergen comprises. Also find out if they process different allergens that may not be part of your product but could cross contaminate before it gets to you. If you’re in any doubt, presume that their ingredient has the allergens. Try to make sure ingredients and raw materials are delivered pre-segregated, and don’t be afraid to reject a delivery if there are any signs of cross contamination.

2. Label all the allergens on your site

2. Label all the allergens on your site

Any allergenic ingredient used on your site should be labelled; it sounds obvious, but it can be overlooked easily. There’s a number of ways to do this, such as tagging the allergens with a specifically coloured label (think yellow for eggs, green for nuts, and so on) or having all 10 allergens on the tag and ticking the ones present. Whichever way you go, just make sure you stick to it.

3. Isolate allergens during storage

Have dedicated, separate storage areas for different allergens, regardless of whether they are there for months or minutes. Do not allow any cross contamination of allergenic ingredients.

4. Show allergens visually

Consider using an image of a peanut instead of using the word when flagging it as an allergen. It’s quicker for the brain to process and easier to understand in today’s multi-national, multi-lingual workforce. Images can be applied to labels or directly onto equipment using using indelible marking.

5. Give each allergen a colour

Colour coding is a universal language, so look to introduce different coloured production utensils and PPE for different allergens. This helps prevent cross contamination by making it easier to identify that the correct utensils are used.

6. Store hygiene equipment properly

Equipment being incorrectly stored is a quick way to the wrong utensil being used in the wrong place, risking contamination. Simple solutions such as colour-coded shadow boards make it quick and easy to see where equipment should be stored, or if there is something missing.

7. What if colours alone are not enough?

Although the EU legislation details 14 allergens that must be controlled, often companies are supplying to customers globally and their allergen requirements may be very different. So, colour alone may not be sufficient to ensure adequate segregation. With an indelible permanent mark, albeit a symbol or a word can be used to identify the utensil to a specific allergen type or ingredient.

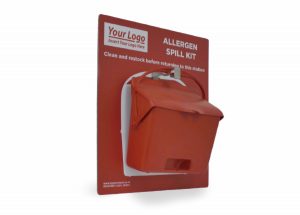

8. Have designated spill stations

8. Have designated spill stations

Allergen spills happen, but it’s how you deal with it that matters. Efficient and effective management starts with having the right equipment in the right places. Consider installing specialist spill stations at strategic points across your business.

9. Train your staff on your allergen strategy and give them specific responsibilities for it

Ensure all staff know the process and protocols for your allergen segregation strategy. Rehearse different scenarios and prepare them so that they know how to react when something does go wrong. Explain to them the importance of why they are doing it as then they are more likely to follow procedure. Show them how it links to consumer safety and therefore your company success. Once trained, all staff need to get behind the process, but specific team members should have specific responsibilities. Ensure all areas and all shifts across the business are covered.

10. Carry out an allergen audit on yourself

Audit your own process regularly to ensure it is still working for your business. If it isn’t – improve it. Revisit it whenever you change suppliers or your product lines. Consider asking external specialists to help with audits to ensure you aren’t missing something due to over familiarity. Address shortcomings and recognise that this is an ongoing process.

Allergen segregation is such a key component in food manufacturing. Getting on top of it is essential to the wellbeing of your customers and your business, so the time for it is now. Hygiene Tech is here to offer solutions to help you achieve compliance with confidence. To find out what we can do to help prevent cross contamination in your facility, get in touch with a member of our friendly team of experts or check out our spill kits online.